Column

secondary×

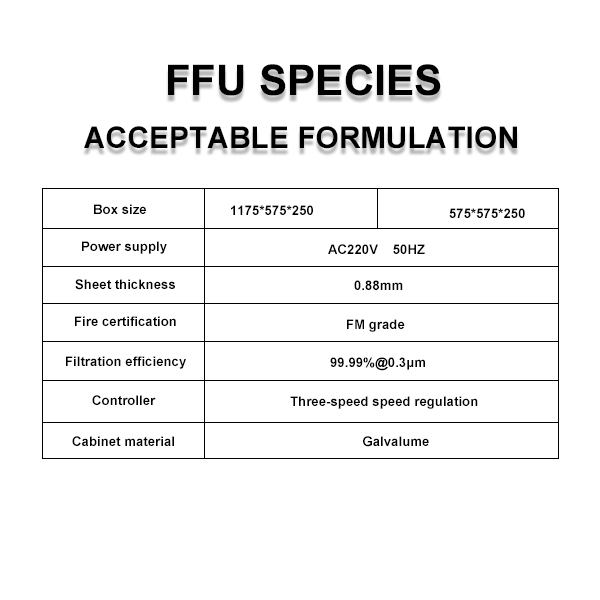

External size(L*W*H):1175*575*250mm

Hepa filter size(L*W*H):1170*570*69mm

Material:Plastic impeler/Aluminum impeler

Efficiency:99.99%@0.3μm

Air Velocity:0.45m/s or 90FPM

Service:Operating manual (including installation), installation videos and online instruction

Application Scene:Microelectronics, medicine, food, chemical, automotive, printing, laboratory, production plant, clean room and other industries

Fan filter units (FFU) are the most energy efficient line of fan filter units on the market today. Designed specifically for use in cleanrooms, medicine manufacturing facilities and laboratories, the FFU delivers high volumes of HEPA filtered air flow (for 99.99% removal of contaminants). Fan filter unit is a self-contained air blower with filtration, the fan draws in air from the top of the FFU and filters it through HEPA filter, and the filtered clean air is evenly sent out over the entire wind surface at a wind speed of 0.45m/s±20%. Cleanroom FFU can be used in modular connection, making cleanroom FFU, widely used in clean rooms. Dust-free operation tables, dust-free production lines assembled cleanrooms and local 100-level applications.

• FFU it has long working hours ,low noise,maintenance-free, small vibration, air velocity uniformity and easy installation and other characteristics.

• FFU modular structure design, making FFU are widely used in clean rooms, clean lines, locally 100 clean class area of the clean room and other applications.

• FFU has pre-filter, HEPA filters.Fan absorb the air flow the top of the FFU and filtered by the pre-filter, then HEPA filter,filtered clean air at 0.45m/s ±20% uniform sent.

• FFU provides high-quality clean air for different sizes, different clean class levels, reduce noise and vibration, and also can greatly reduce the cost,easy installation and maintenance, is an ideal component of a clean environment.

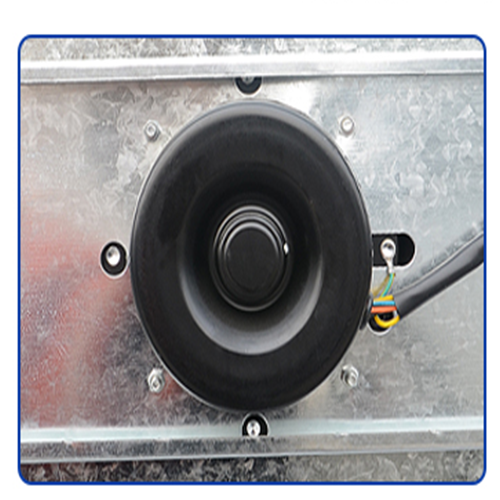

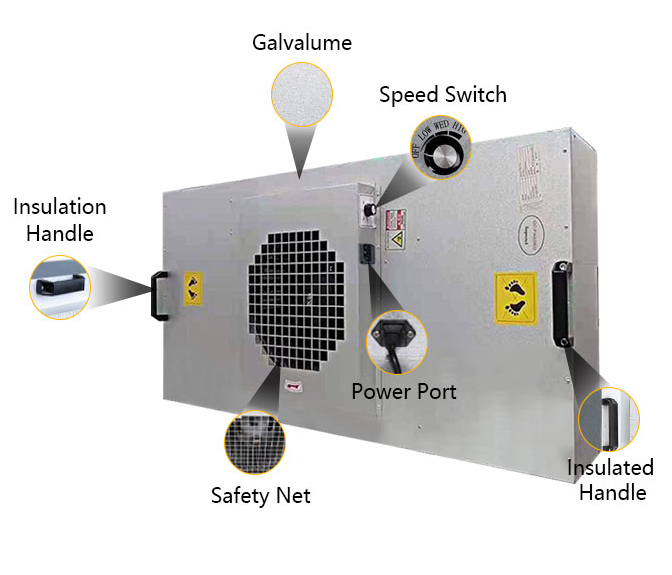

Pure copper motor, energy-saving and quiet

Three speed control, simple operation

Safety net, effective protection

High efficiency filter, fast filtration

Inventory, standard sizes are in stock

Package

Production equipment

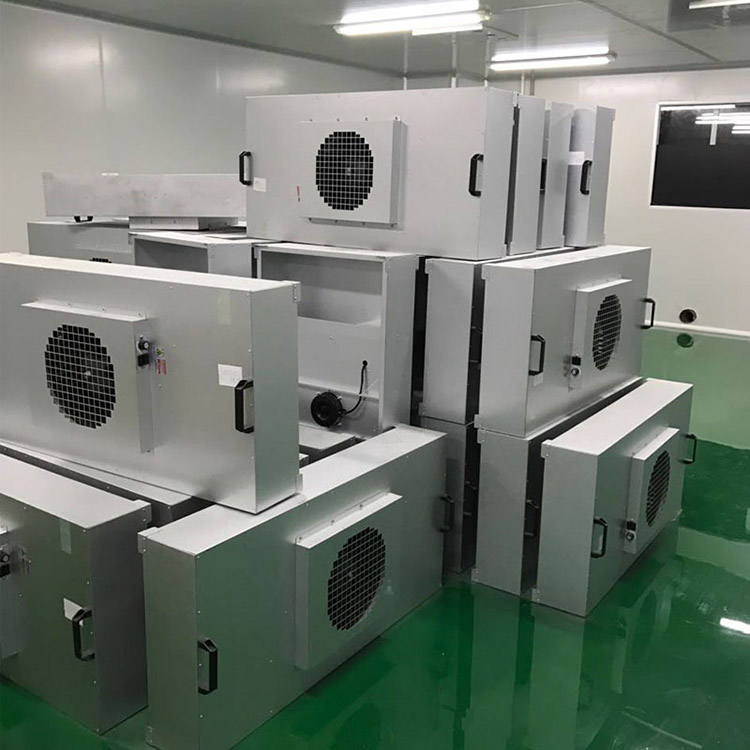

Delivery photo

(1) Low, medium and high speeds control the fan filter unit speed.

(2) The built-in air duct diversation system reduces noise and pressure loss and improves fan efficiency.

(3) Easily matched with a variety of high-efficiency filters and HEPA,ULPA.

(4) The rear-tilt centrifugal provides high air volume.High static pressure conditions and long working life.

(5) Suitable for clean room Class 100-100000 clean room.

(6) It is especially suitable for assembly into a super-clean production line, which can multiple units can be connected in series into a Class 100 flow assembly line.

The fan filter unit is a motorised which supplies clean,filtered air to a cleanroom.Air is drawn via the fan,through a pre-filter and then through a HEPA or ULPA filter which filters the sub-micron particles ensuring a clean and processed air supply.Using fan filter units to provide localised clean air is a more energy efficient route than using a traditional Air Handling Unit(AHU) and is a more frequently adopted approach in modern cleanroom design.

We can provide consultation and free quotation services for air showers. If you need air showers, get in touch today! Don't hesitate. And we will contact you as soon as possible.